Quartz Powder Grinding Plant

About quartz powder

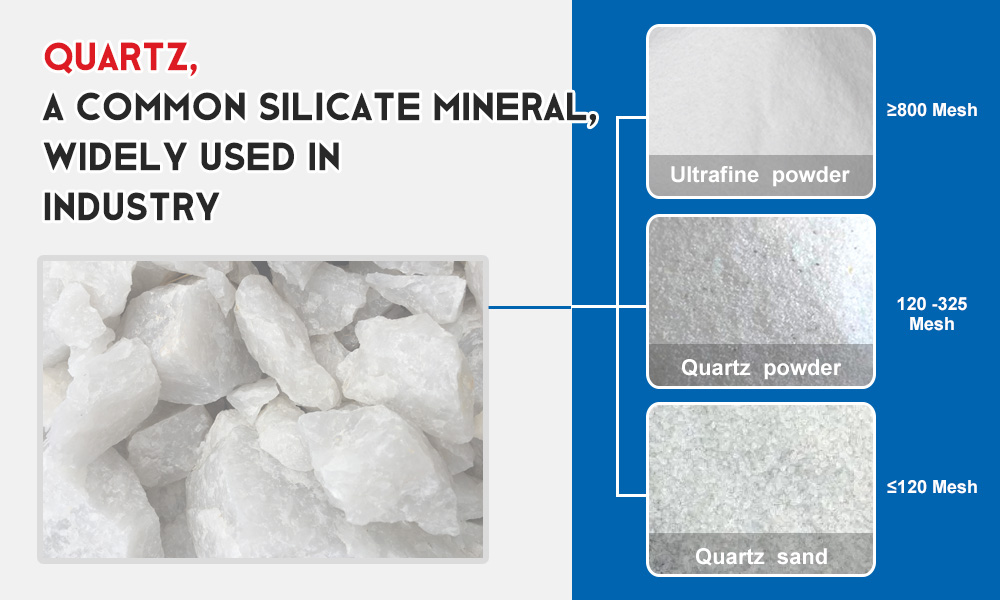

Quartz powder is also called silicon powder. The fineness of quartz powder is usually expressed in "mesh". Products with different fineness have different application fields:

- Quartz products below 120 mesh are usually called quartz sand, which is mainly used in foundry, metallurgy, building materials and other fields.

- Quartz products with a mesh size of 120 or above are called quartz powder (silicon powder).

- 200 mesh and 325 mesh quartz products are commonly used in ceramics, refractory materials, chemicals, rubber fillers, etc.

- Ultrafine powder above 800 mesh: used in high-end ceramics, precision casting, electronic packaging materials, coatings, medicine and other fields with extremely high requirements on purity, whiteness and particle size.

We provide quartz powder grinding equipment and systematic solutions.

Quartz powder mill

The selection of quartz powder mill is very important, as it affects the fineness of the finished product, output and production efficiency.We usually provide three types of mills according to needs.The three types of mills are ball mill, Raymond mill and vertical mill.

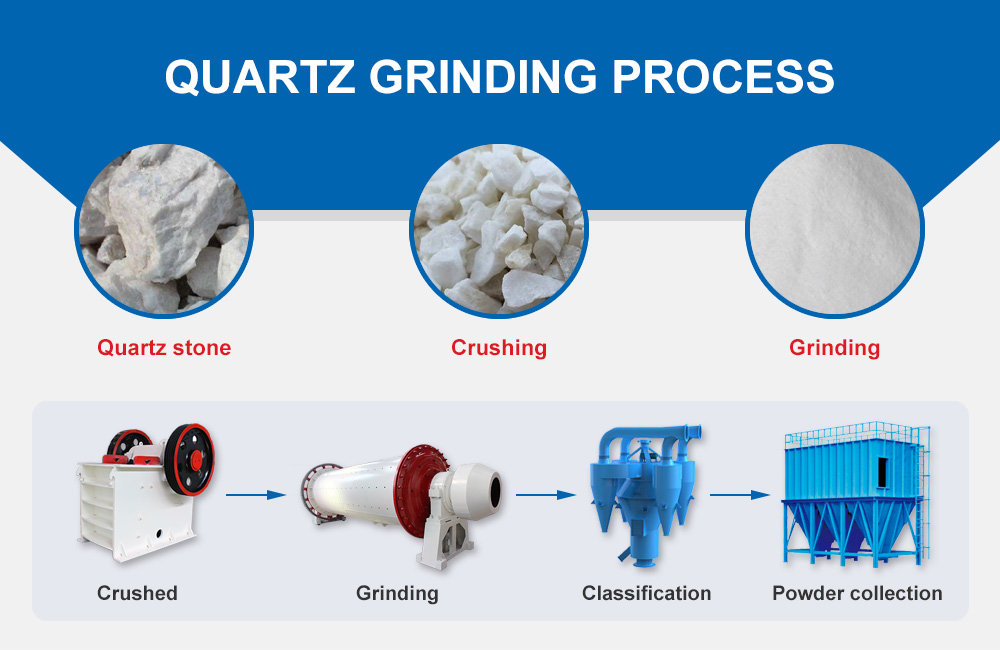

Complete quartz grinding plant

Crushing system: The large quartz stones are fed into the jaw crusher by the vibrating feeder for coarse crushing, and then crushed into the particle size that can enter the grinding mill (generally less than 30mm-50mm

Grinding system: The crushed quartz stone is sent to the silo by the elevator, and then sent to the grinding machine (such as Raymond mill, ball mill, etc.) for grinding evenly and quantitatively through the feeder.

Classification: The ground quartz powder will be classified by a powder selector or analyzer, and the powder that does not meet the fineness requirements will be returned to the grinding mill for re-grinding.

Powder collection: Finished powder that meets the fineness requirements will enter the dust collector with the air flow for separation and collection. The collected finished powder will be sent to the finished product silo by the conveying device through the discharge port and finally packaged.

Advantages of our quartz grinding plant

With 30 years of experience in milling equipment production and milling solution design, we are your trusted partner.

Our grinding equipment is easy to operate and does not require senior operators to ensure stable operation of the equipment.

We have a strong after-sales team ready to serve you at your site at any time.