Gypsum Powder Mill Plant

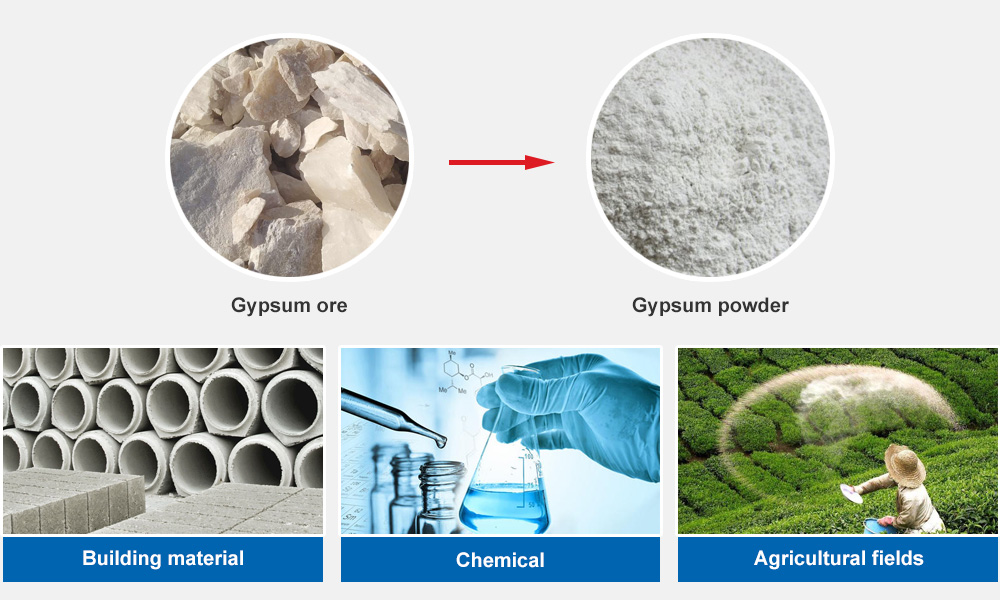

About gypsum powder

Gypsum powder is a multifunctional material that can be divided into two categories: raw gypsum and parched gypsum according to its processing technology and composition.It is mainly used as a building material and also has applications in the chemical and agricultural fields.

We provide gypsum powder grinding equipment and systematic solutions.

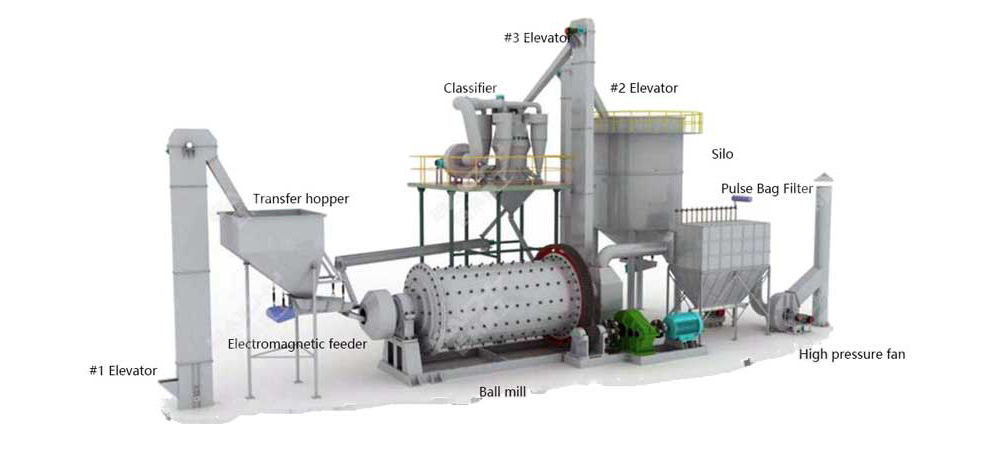

Gypsum powder grinding system

Gypsum powder production line is the natural dihydrous gypsum ore (gypsum) or industrial by-product gypsum (desulfurized gypsum, phosphogypsum, etc.) through grinding mill and after a certain temperature heating calcination, so that the dihydrous gypsum dehydration decomposition, the generation of β semi-hydrous gypsum (CaSO4 1/2H2O) as the main component of the product, that is building gypsum.

1. Gypsum Crusher: Raw gypsum is first crushed into smaller particles by a crusher to facilitate the grinding process.

2. Gypsum Grinding Mill: The crushed gypsum is then sent to a grinding mill where it is ground into a fine powder. Common types of grinding mills for gypsum include ball mills, Raymond mills, vertical roller mills, and ultrafine mills.

3. Classifier: A classifier is often used to control the particle size distribution of the ground gypsum powder. It separates the fine particles from the coarse ones and ensures a consistent product quality.

4. Dust Collector:A dust collector is essential to collect and remove airborne dust generated during the grinding process, ensuring a clean and safe working environment.

5. Packaging Machine:Once the gypsum is ground to the desired fineness, it is packaged using a packaging machine for storage or transportation.

Gypsum powder grinding mill

The gypsum powder grinders are the core equipment of calcium carbonate plants. Here are 3 top-selling mineral grinding mills. Choose the best one based on the required particle size range, required production capacity, operating costs, and specific application.

Ball mill

The gypsum powder ball mill works by rotating a cylinder with grinding media, causing the media to fall back into the cylinder and on to the material to be ground. The ball mill can be operated either wet or dry. The particle size of the finished product can be adjusted by controlling the grinding time, rotating speed, size and composition of grinding media, additives, etc.

Typically, ball mills can produce fine calcium carbonate powders with particle size distributions ranging from approximately 20 mesh to 200 mesh. They are popular in large calcium carbonate grinding plants due to high throughput.

Raymond Mill

The working principle of Raymond mill is that the blades installed on the base shovel limestone or marble into the vertical gap between the grinding rollers and the grinding ring. The material is squeezed into powder.

Its working principle determines that the proportion of fine powder produced is relatively low. For example, in the 400 mesh calcium carbonate powder, the fine powder below 10μm accounts for about 35%, and the fine powder below 5μm is only 5%, which is much lower than other calcium carbonate mills.

Therefore, using a Raymond mill to make 40-400 mesh calcium carbonate powder has competitive advantages in terms of investment and energy consumption.

HGM ultrafine mill

HGM ultrafine mill has the same working principle as Raymond mill. Two improvements increase its grinding efficiency and fine powder production efficiency. One is that the high-pressure spring device improves the grinding pressure of the grinding rollers. The other is that the improved classifier can precisely adjust the fineness of the finished products.

It is economical to make 800-2500 mesh calcium carbonate powder with an ultrafine mill.

Advantages of our gypsum powder grinding plant

With 30 years of experience in milling equipment production and milling solution design, we are your trusted partner.

Our grinding equipment is easy to operate and does not require senior operators to ensure stable operation of the equipment.

We have a strong after-sales team ready to serve you at your site at any time.