Calcium Carbonate Grinding Mill Plant

About Calcium Carbonate Powder Mill Plant

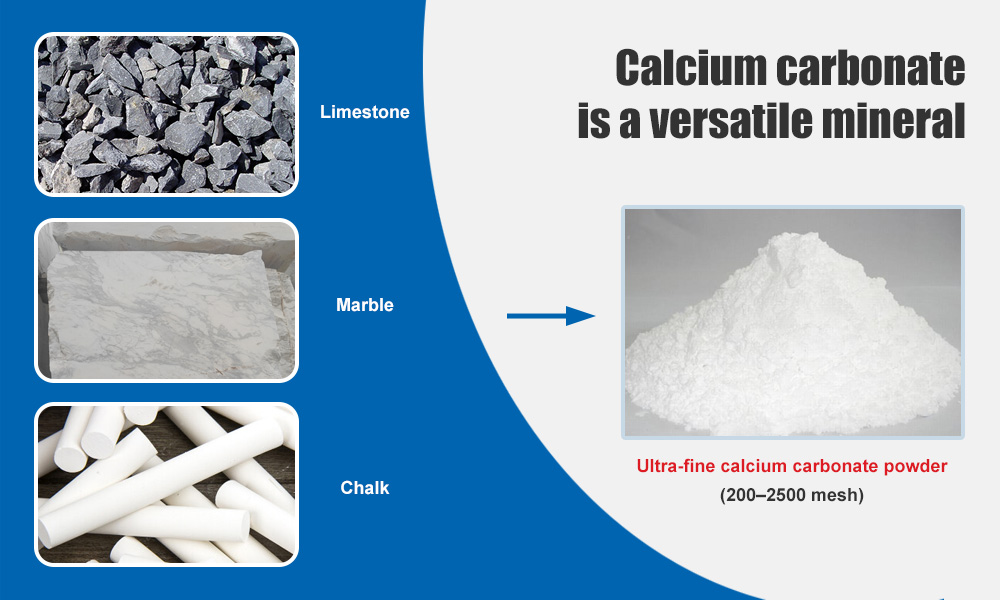

Calcium carbonate (CaCO₃) is a versatile mineral used in industries ranging from plastics and paper to pharmaceuticals and construction. To meet the demand for ultra-fine calcium carbonate powder (typically 200–2500 mesh), a well-designed grinding mill plant is essential. A calcium carbonate grinding mill plant is a specialized production line that transforms raw calcium carbonate ore (limestone, marble, or chalk) into fine powder. The process involves crushing the raw material, grinding it to the desired fineness, and collecting the finished powder—all while ensuring particle uniformity and purity, which are critical for end-use applications (e.g., as a filler in plastics or a coating in paper).

We provide calcium carbonate grinding equipment and systematic solutions.

Main Components of Calcium Carbonate Grinding Mill Plant

A typical calcium carbonate grinding plant includes the following key equipment and processes:

1. Raw Material Storage & Feeding

• Limestone or marble is stored in silos or bins.

• A vibrating feeder or belt conveyor controls the feed rate into the grinding system.

2. Crushing (if needed)

• Large chunks of limestone are first crushed by a jaw crusher or hammer crusher to reduce them to sizes suitable for grinding (usually below 20–30 mm).

3. Grinding Mill (Core Equipment)

• This is the heart of the plant where calcium carbonate is ground into fine powder. Ultrafine Mill or Ultrafine Vertical Mill is for producing fine powders (325–2500 mesh or even finer).

4. Classifier (Air Classifier or Mechanical)

• Separates fine particles from coarse ones.

• Ensures the final product has the desired particle size distribution.

5. Dust Collection & Air Filtration

• A baghouse dust collector or cyclone separator captures fine powders and ensures clean air emission.

Calcium carbonate grinding mill

Calcium carbonate grinders are the core equipment of calcium carbonate plants. Here are 3 top-selling mineral grinding mills. Choose the best one based on the required particle size range, required production capacity, operating costs, and specific application.

Ball mill

The calcium carbonate ball mill works by rotating a cylinder with grinding media, causing the media to fall back into the cylinder and on to the material to be ground. The ball mill can be operated either wet or dry. The particle size of the finished product can be adjusted by controlling the grinding time, rotating speed, size and composition of grinding media, additives, etc.

Typically, ball mills can produce fine calcium carbonate powders with particle size distributions ranging from approximately 20 mesh to 200 mesh. They are popular in large calcium carbonate grinding plants due to high throughput.

Raymond Mill

The working principle of Raymond mill is that the blades installed on the base shovel limestone or marble into the vertical gap between the grinding rollers and the grinding ring. The material is squeezed into powder.

Its working principle determines that the proportion of fine powder produced is relatively low. For example, in the 400 mesh calcium carbonate powder, the fine powder below 10μm accounts for about 35%, and the fine powder below 5μm is only 5%, which is much lower than other calcium carbonate mills.

Therefore, using a Raymond mill to make 40-400 mesh calcium carbonate powder has competitive advantages in terms of investment and energy consumption.

HGM ultrafine mill

HGM ultrafine mill has the same working principle as Raymond mill. Two improvements increase its grinding efficiency and fine powder production efficiency. One is that the high-pressure spring device improves the grinding pressure of the grinding rollers. The other is that the improved classifier can precisely adjust the fineness of the finished products.

It is economical to make 800-2500 mesh calcium carbonate powder with an ultrafine mill.

Advantages of our calcium carbonate grinding plant

With 30 years of experience in milling equipment production and milling solution design, we are your trusted partner.

Our grinding equipment is easy to operate and does not require senior operators to ensure stable operation of the equipment.

We have a strong after-sales team ready to serve you at your site at any time.

We provide calcium carbonate grinding equipment and systematic solutions.